Cuvette for Specific Protein Analyzer: Precision Consumables That Define Analytical Accuracy

In clinical diagnostics and laboratory testing, analytical accuracy is determined not only by the performance of the analyzer itself but also by the quality of the consumables used during measurement. Among these consumables, the cuvette for specific protein analyzer plays a decisive role in ensuring reliable optical detection, stable sample handling, and repeatable test results.

Specific protein analyzers are widely applied in hospitals, diagnostic laboratories, research institutions, and industrial laboratories to measure proteins such as CRP, microalbumin, transferrin, immunoglobulins, and other clinically relevant markers. The cuvette used in these analyzers is not a simple container—it is a precision optical component that directly affects absorbance readings, reaction consistency, and overall assay reliability.

This article provides a comprehensive, application-focused explanation of cuvettes for specific protein analyzers, examining their functional role, material characteristics, compatibility considerations, and quality requirements from a professional B2B and laboratory perspective.

What Is a Cuvette for Specific Protein Analyzer?

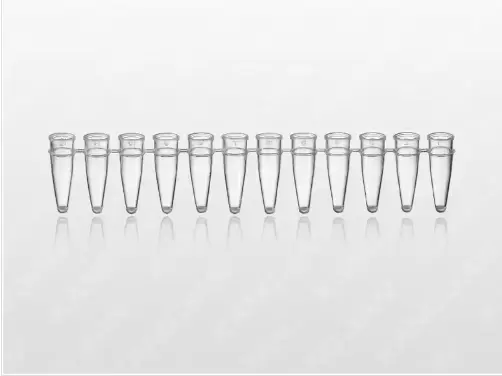

A cuvette for specific protein analyzer is a specially designed optical reaction vessel used to hold liquid samples and reagents during protein concentration measurement. Unlike general laboratory containers, these cuvettes are manufactured with strict dimensional tolerances and optical clarity requirements to ensure accurate photometric analysis.

During testing, light emitted from the analyzer passes through the cuvette and the reaction solution. The analyzer then measures absorbance or turbidity changes caused by antigen–antibody reactions or other biochemical processes. Any variation in cuvette transparency, wall thickness, or surface quality can directly influence measurement accuracy.

Therefore, cuvettes used in specific protein analyzers are considered critical consumables rather than interchangeable accessories.

Functional Role of Cuvettes in Specific Protein Analysis

Optical Transmission and Signal Accuracy

Specific protein analyzers rely on precise optical detection principles. The cuvette must allow consistent and uniform light transmission across the measurement wavelength range. A high-quality cuvette for specific protein analyzer ensures that optical signals are affected only by the reaction chemistry, not by imperfections in the cuvette itself.

Uniform wall thickness and smooth internal surfaces help minimize light scattering and background noise, supporting stable absorbance readings throughout repeated test cycles.

Reaction Stability and Sample Integrity

Protein assays often involve sensitive immunochemical reactions. The cuvette must provide a chemically inert environment that does not interact with reagents or samples. Any adsorption of proteins onto cuvette walls or leaching of additives can distort results.

A properly designed cuvette for specific protein analyzer maintains sample integrity throughout the reaction process, ensuring that measured values reflect true protein concentrations.

Compatibility with Automated Analyzer Systems

Modern specific protein analyzers operate in automated or semi-automated workflows. Cuvettes must be precisely dimensioned to fit analyzer trays, holders, or robotic handling systems.

A well-matched cuvette for specific protein analyzer supports smooth sample loading, stable positioning during measurement, and reliable disposal or reuse depending on analyzer design.

Common Materials Used in Cuvettes for Specific Protein Analyzer

Optical-Grade Plastic Cuvettes

Many analyzers use disposable plastic cuvettes due to their cost efficiency and convenience. Optical-grade plastics such as polystyrene or PMMA are commonly used when manufactured under strict quality control.

These materials provide:

High optical transparency

Low batch-to-batch variation

Compatibility with routine clinical protein assays

Disposable plastic cuvettes for specific protein analyzer reduce cross-contamination risk and simplify laboratory workflows.

Quartz and Glass Cuvettes for Specialized Applications

In certain laboratory environments, reusable quartz or glass cuvettes are employed. These materials offer superior optical performance and chemical resistance.

Quartz cuvettes for specific protein analyzer are particularly suitable when assays require high UV transparency or extended measurement stability. However, they require careful cleaning and handling to maintain accuracy.

Structural Design Features of Specific Protein Analyzer Cuvettes

Optical Path Length Control

The optical path length—the distance light travels through the sample—is a critical parameter in protein measurement. A cuvette for specific protein analyzer is manufactured with tightly controlled path lengths to ensure consistent absorbance calculations.

Even minor deviations in path length can result in measurable errors, especially in high-sensitivity assays.

Precision-Molded Internal Geometry

The internal geometry of the cuvette affects how the reaction mixture behaves during mixing and measurement. Smooth internal walls and consistent internal volume help ensure homogeneous reactions.

This structural precision supports repeatable assay performance across thousands of tests.

Secure Sealing and Sample Containment

Some analyzer systems require cuvettes with lids, caps, or sealing features to prevent evaporation or contamination. A properly designed cuvette for specific protein analyzer maintains a stable microenvironment during the entire testing cycle.

Compatibility Considerations When Selecting a Cuvette for Specific Protein Analyzer

Analyzer Model Matching

Cuvettes are often analyzer-specific. Differences in size, shape, and positioning requirements mean that not all cuvettes are universally compatible.

When sourcing a cuvette for specific protein analyzer, laboratories and distributors must ensure full compatibility with the target analyzer model to avoid mechanical errors or inaccurate readings.

Reagent and Assay Compatibility

Protein assays vary in reagent composition and reaction conditions. The cuvette material must be compatible with buffers, antibodies, and detection agents used in the assay.

A high-quality cuvette for specific protein analyzer is tested to ensure chemical stability under typical assay conditions.

Single-Use vs. Reusable Workflow Alignment

Some laboratories prioritize disposable cuvettes for infection control and efficiency, while others prefer reusable options for cost management. Selecting the appropriate cuvette for specific protein analyzer depends on laboratory workflow, throughput, and quality control protocols.

Quality Requirements for Medical and Laboratory Use

Dimensional Consistency Across Batches

Inconsistent cuvette dimensions can introduce variability in test results. Professional-grade cuvettes for specific protein analyzer are manufactured using high-precision molds and monitored through strict quality assurance processes.

Batch consistency is especially important for laboratories performing longitudinal studies or routine diagnostics.

Optical Clarity and Surface Finish

Scratches, bubbles, or inclusions within the cuvette material can interfere with optical detection. Each cuvette for specific protein analyzer must meet defined clarity standards to ensure accurate and stable readings.

Advanced inspection methods are often used during production to detect micro-defects.

Cleanliness and Contamination Control

Medical and diagnostic applications demand high cleanliness levels. Cuvettes are typically produced in controlled environments and packaged to prevent particulate contamination.

A clean cuvette for specific protein analyzer reduces the risk of assay interference and false results.

Role of Cuvettes in High-Throughput Protein Testing

Supporting Continuous Analyzer Operation

In laboratories processing large sample volumes, cuvettes must support continuous analyzer operation without interruption. Consistent cuvette quality minimizes analyzer errors and downtime.

A reliable supply of uniform cuvette for specific protein analyzer ensures uninterrupted testing capacity.

Reducing Retesting and Waste

Inaccurate results caused by substandard consumables often lead to retesting, reagent waste, and increased labor. High-quality cuvettes reduce these inefficiencies by providing stable performance across all test cycles.

Storage, Handling, and Usage Best Practices

Proper Storage Conditions

Cuvettes should be stored in clean, dry environments away from direct sunlight and extreme temperatures. Proper storage helps maintain optical properties and structural integrity.

Handling to Preserve Optical Surfaces

Operators should avoid touching optical surfaces directly, as fingerprints and residues can affect light transmission. Careful handling preserves the functional performance of each cuvette for specific protein analyzer.

Disposal and Reuse Considerations

Disposable cuvettes should be discarded according to laboratory waste protocols. Reusable cuvettes require validated cleaning procedures to prevent residue buildup and cross-contamination.

Value of Reliable Cuvette Supply in B2B and OEM Contexts

Supporting Diagnostic Equipment Manufacturers

For OEMs producing specific protein analyzers, the cuvette is an integral part of the analytical system. Consistent cuvette quality helps ensure that analyzer performance specifications are met in real-world use.

Meeting Hospital and Laboratory Procurement Standards

Hospitals and diagnostic labs require consumables that meet strict quality and compliance expectations. A dependable cuvette for specific protein analyzer supports regulatory compliance and laboratory accreditation requirements.

Long-Term Performance Stability

Stable consumable performance strengthens customer confidence and reduces technical support demands. High-quality cuvettes contribute to the overall reliability of protein analysis systems.

Why Cuvette Quality Matters in Specific Protein Measurement

A specific protein analyzer can only perform as accurately as the consumables it relies on. The cuvette for specific protein analyzer directly influences optical precision, reaction stability, and measurement repeatability.

By selecting cuvettes with controlled dimensions, high optical clarity, and verified compatibility, laboratories and manufacturers can achieve:

More reliable analytical results

Lower variability across test batches

Improved operational efficiency

Greater confidence in diagnostic outcomes

In professional diagnostic environments, the cuvette is not a minor accessory—it is a foundational component of accurate protein analysis.